INDUSTRIAL CONTROL

A MORE CAPABLE ETHERNET

Industrial suppliers, IT vendors, and silicon providers are collaborating in IEEE 802 and Avnu to create updates to standard Ethernet which will provide:

- Efficient management & control

- Convergence of traffic with mixed criticality

- Security enhancements aligned with IT standards

These improvements will enable a single network to support reliable multi-kHz closed-loop control and dynamic unmanaged standard Ethernet traffic. TSN enables the convergence of networks and systems that were previously kept separate for operational integrity, real-time performance, safety, or security reasons. Breaking down communication barriers between critical and noncritical systems is a foundational concept of IIoT and Industry 4.0. Because TSN is part of standard Ethernet, control networks can take advantage of best practices for security that have been developed into Ethernet for decades. TSN also adds flexible traffic “policing” functions, which provide additional protections against traffic storms and other forms of attack.

TSN also scales naturally with Ethernet, which means that the technology will no be limited regarding bandwidth and other performance criteria. In addition, new nodes can be easily added and discovered via standard networking protocols.

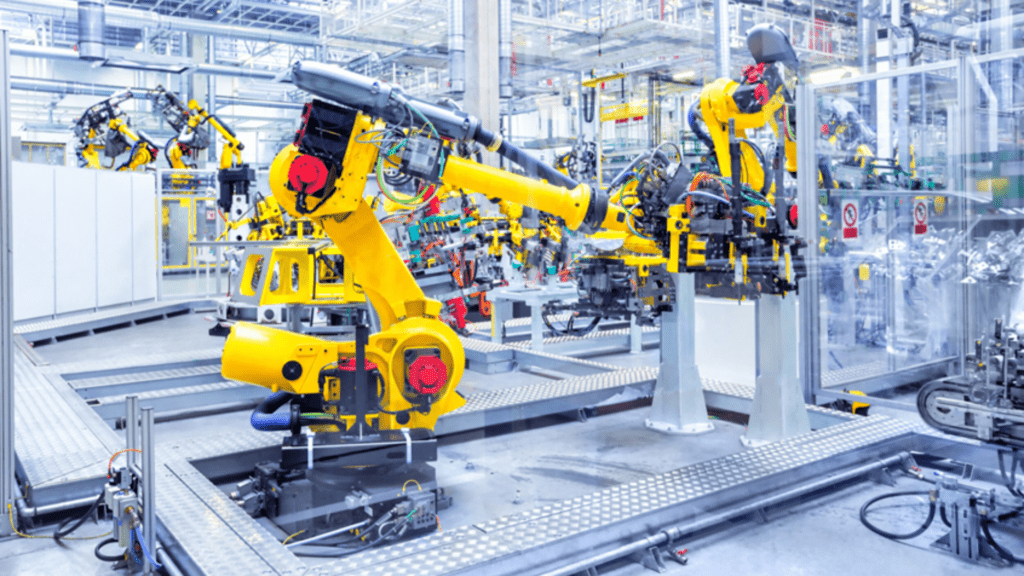

CONVERGED NETWORKS FOR DIGITAL FACTORY

IIoT industries are all moving beyond single-function networks to realize the benefits of a converged network foundation with the coexistence of different traffic types and devices on the same physical network. TSN provides the tools to enable this convergence and the exchange of real-time control, telemetry, and general IT information, all managed securely by IT and OT, reducing infrastructure costs and the resources needed to manage and maintain the network. Factory automation, process automation, motion control, predictive maintenance, and professional audio-video are all applications that can benefit from converged networking.

ECOSYSTEM

Avnu has joined with protocol organizations including CC-Link Partner Association, ODVA, OPC Foundation, and PROFIBUS & PROFINET International to develop a single test plan that could test for conformance with the IEEE/IEC 60802 profile for TSN for Industrial Automation. This initiative is called the TSN Industrial Association Conformance Collaboration (TIACC). The announcement of the TIACC cooperation on TSN interoperability will be key to having common approaches to using TSN in industrial settings and converged networks. In addition, the leading silicon vendors are working together in Avnu Alliance to develop a foundation of silicon and IP products’ for endpoint and switches with TSN capabilities at the component and supporting software level. This effort will support cross-industry collaboration and help the industry more quickly and easily build these products.